Polysulfone PSU/PSF

- Release Time: 2021-04-17

- Read: 2741

I. Introduction to performance:

Polysulfone PSU/PSF is slightly amber amorphous transparent or translucent polymer, and it is featured with excellent mechanical properties, rigidity, wear resistance, and high strength. Its excellent mechanical properties can be maintained even at high temperature, which is its outstanding advantages; specifically, the temperature range is -100-150℃, the long-term use temperature is 160℃, the short-term use temperature is 190℃, and the thermal stability is high. It has good radiation stability, low ionic impurities and good chemical and hydrolysis resistance, excellent precipitation resistance (suitable for use in the sterilization chamber using steam disinfection), through infrared light and microwave radiation. In addition, it also hydrolysis resistance, good dimensional stability, forming shrinkage rate is small, non-toxic, radiation resistance, fire resistance, extinguishing.

II. Application fields:

1. Electrical and electronic

At present, electrical and electronic products are the major consumers of PSF. The development of electronic and electrical products towards small, light weight and high temperature resistance, and this has promoted the growth of PSF consumption. PSF can be used to make all kinds of contactors, contacts, transformer insulation parts, thyristor caps, insulation bushings, coil skeleton, terminals and electrical rings and other electrical parts, printed circuit boards, sleeve, cover, film and television system parts, capacitor film, brush holder, alkaline battery case, etc.

2. Automobile and aviation

In the field of aerospace and automotive manufacturing, PSF is suitable for the production of protective cover components, electric gear, battery cover, detonator, electronic ignition device components, lighting components, aircraft internal parts and aircraft external parts, spacesuit external protective cover, etc. In addition, PSF can also be used for the production of illuminator baffles, electric drives, sensors. Due to the fact that they emit less heat when burned, produce less smoke, diffuse less toxic gases, and meet the requirements for safe use, the demand for polysulfone polymers used in engine room components is growing worldwide.

3. Cookware and food processing machinery

PSF is a non-toxic product confirmed by United States FDA. It can be made into repeated contact with food appliances. PSF as a new transparent material, its water resistance and hydrolysis stability are better than other thermoplastics, and it can replace glass and stainless steel products and meet the required performance standards.

In the market of kitchen products, PSF products include steaming plates, coffee containers, microwave cookers, milk and produce containers, egg cookers and milking equipment components, beverage and food dispensers, etc. In the aspect of food packaging, PSF can be used in a variety of containers by using its good microwave permeability characteristics to make microwave utensils. In addition, PSF can also be used as a connecting pipe, the outer layer of the pipe is high strength, the inner layer is resistant to chemicals, lighter and transparent than the steel pipe, easy to control, and it is often used in food industry and the production of strong light lamp lampshade.

In the field of health and medical care, PSF fully meets the health requirements, and it can withstand 130℃ steam repeated disinfection, can be used in health and medical equipment, can replace stainless steel, aluminum and so on to reduce costs. Medical instruments that can be made by PSF include: surgical disc, sprayer, humidifier, contact lens fixture, flow controller, instrument cover, dental instruments, pacemaker, respirator, etc. Compared with glass products, medical products made of PSF cost less and are not easy to break, so they are used in instrument shells, dental instruments, heart valve boxes, blade cleaning systems, soft contact lens molding boxes, micro filters, dialysis membranes, etc. Moreover, it can also be used for dental implants, which are twice as strong as polyacrylate.

4. Commodity application

The daily necessities produced by PSF are mainly heat-resistant and hydrolyzation-resistant products, such as humidifier, steam iron, camera box, projector components, etc.

5. Adhesives, coatings

All polysulfones with silane can be used as adhesives, and used for sizing glass fiber and graphite fiber to make composite materials. Aeronautical components such as elevators can be made from PSF reinforced by graphite fabric with silicate alkyl. PSF and solid lubricant polytetrafluoroethylene can be used to make wear resistant coatings. For industrial application, PSF can also manufacture a variety of chemical processing equipment, such as pump cover, tower outer protective cover, food processing equipment, pollution control equipment, dairy processing equipment and engineering, construction, chemical pipeline, etc

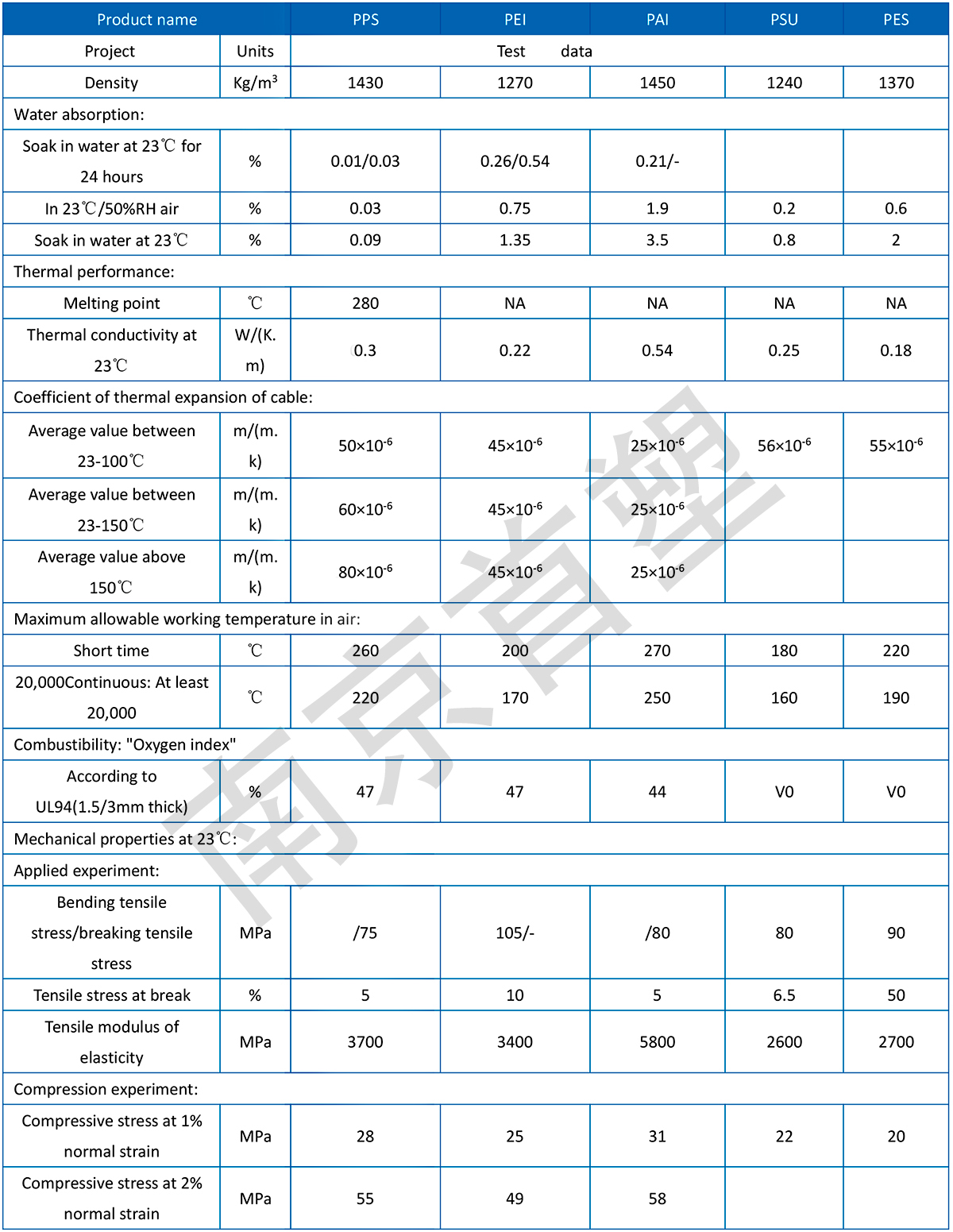

III.Parameter table of other engineering plastics: